The Art of Gear Design

The art of gear design is extremely specific and precise and how you manufacture or process the gear will significantly impact its performance and cost. That is why you need a resource that is experienced in developing the right manufacturing process. This process involves collecting, interpreting and correctly applying all the customer’s quality requirements, controlling specifications, specialty third party processing, tooling and fixture needs, cutters, operational drawings, routings, inspection criteria, etc. while matching the tolerances to the right process.

Mondek Solutions is that experienced resource. We can take your print and controlling documentation and generate the manufacturing process needed to produce the gear. Whether it is a replacement part, a new PMA opportunity, or an initiative to insource or outsource, we will engineer the process as needed to comply with your customers’ needs. Once complete you will be provided a complete set of documents to produce the part. This will include but not be limited to:

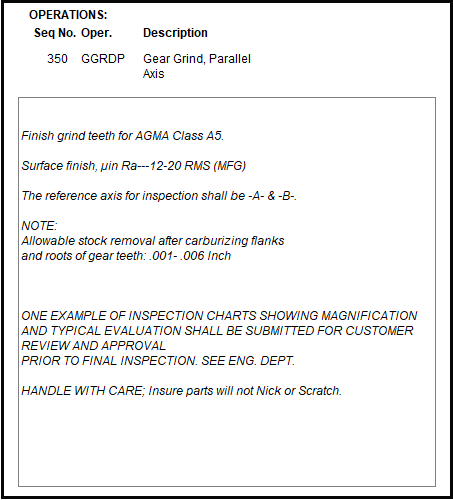

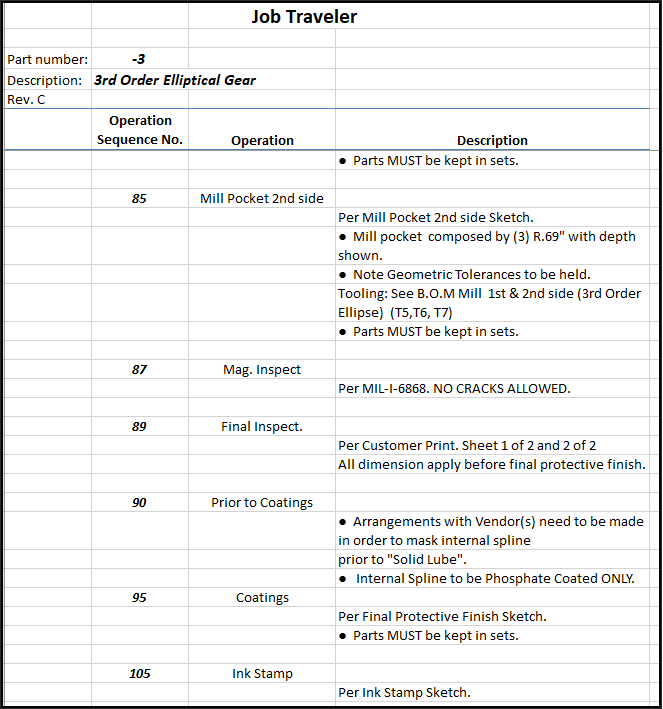

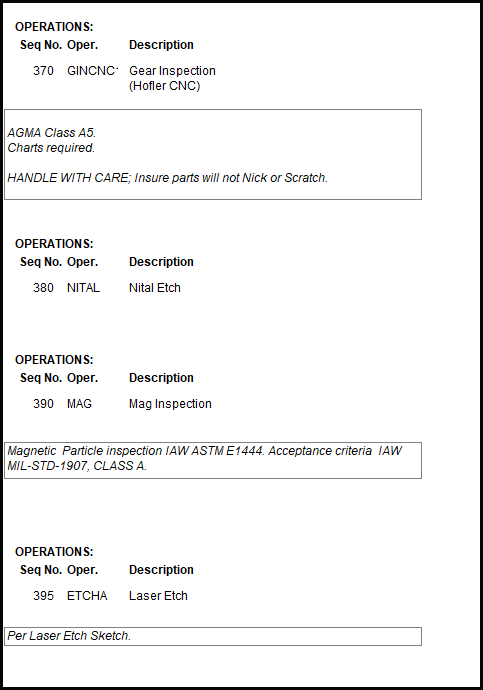

- Complete process routing details from blank to final inspect and pack

- Tooling design for bevel cutting and testing.

- Tool design for Parallel axis gears, for hobbing and shaping.

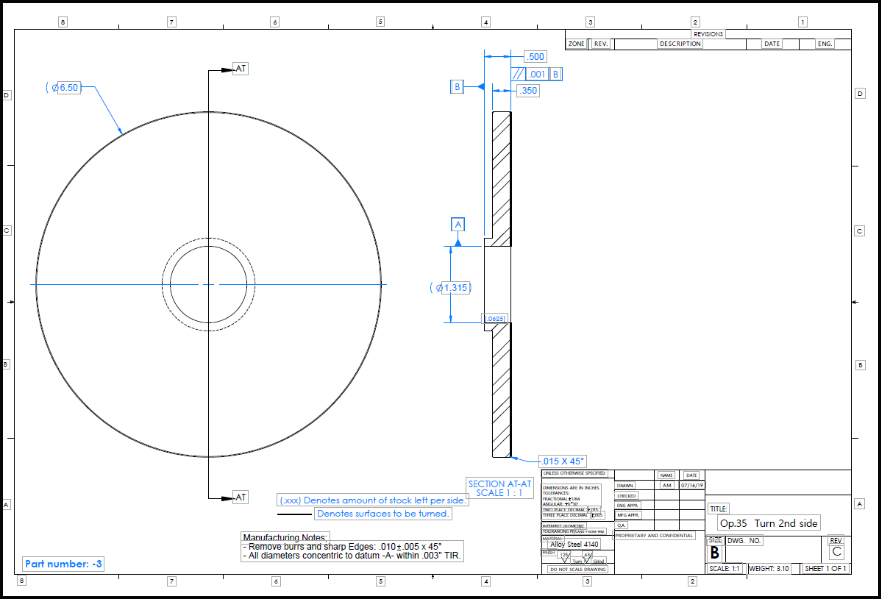

- Detailed gear manufacturing process/operational prints (Turn, Mill, Heat Treat, Grind, Plating, etc.)

- Mechanical Design (Hob and Shaping Fixtures, Gleason Gear Cutting & Tooth Grind Arbors, and fixtures)

- First Article Inspection and In-process Inspection Documents for: AS9102, PPAP, Control Plans)

Having worked within the industrial, aviation, DOD, and other markets we are well versed on the many mil spec , quality, and customer specific standards along with AS9100, ISO, ITAR, DPAS, etc.

For more information about how we can help you with your gear process manufacturing needs contact us at 855-282-4867 or by email at info@mondeksolutions.com.